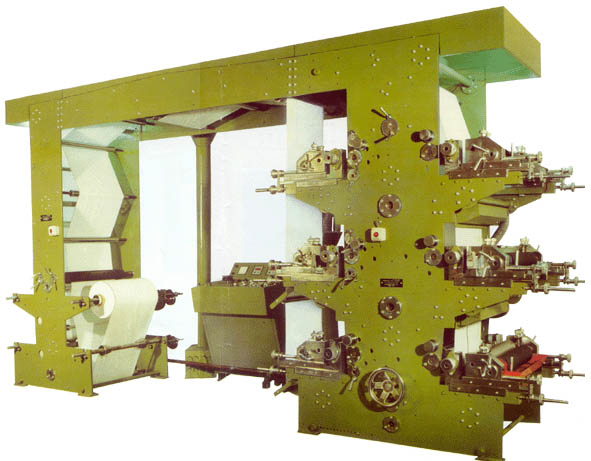

The range of application covers particularly the printing of flexible packaging means such as Low Density and High Density polythylene, polypropylene, polyester and co-extruded film, tissue paper, BOPP, etc...

Click for Enlarged View

Salient Features:

- Heavy Duty M.S.Plate frame.

- Best quality electronic devices.

- Vibration free running.

- Ease of Operation.

- Highly precise printing quality.

- High speed

- Registration accuracy.

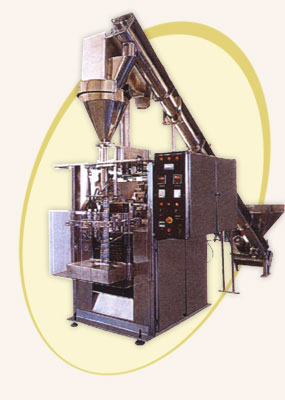

The Automatic Bottom Cutting & Sealing Machine is used for HM, HMHD, LDPE, LLDPE, PP, BOPP, CO-EX & other films. The basic Machine consists of: ONE: Main Drive. ONE: Unwinder (two station). ONE: Receiving tray. ONE: Electrical control panel. ONE: Static electric Eliminator. ONE: Scanner for registration of printed film (i.e. Photocell)

Click for Enlarged View

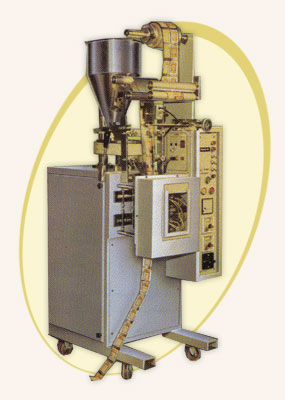

The range of application covers Side Cutting and Sealing material of flexible packaging such as Low Density and High Density Polythylene, Polypropylene, Polyester and Co-extruded film, BOPP etc... Technical design and performance of these machines have proven advantages like

Ease of operation

Precision Cutting and Sealing

High speed

Accurate Registration

High efficiency, Economy & Larger Output.

Click for Enlarged View

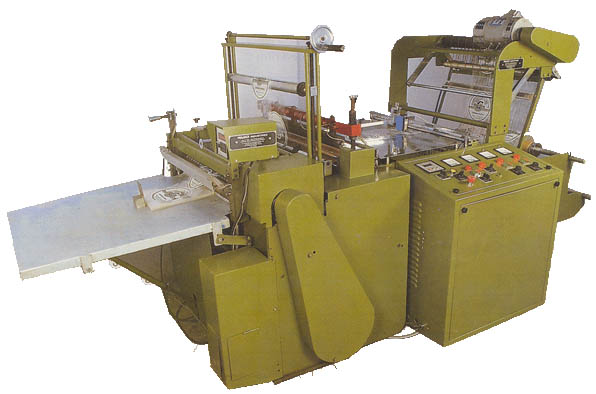

Salient Features:Extruder Fitted with A.C. motor (EDDY Current & D.C. motor on request) Screw Barrel made from En 41 B quality alloy steels with Gas Nitriding. DIE Spiral Die with Mirror finish & Hardchrome Plated. Excellent Gauge Control. Aluminium air ring with high power blower. TAKE-OFF UNIT Adjustable Take-off with one Rubber & Steel Roller. Drive by D.C. Motor with control. WINDER Two station winder Drive by two torque motors with control.

Click for Enlarged View